Model No.︰-

Brand Name︰TOPO

Country of Origin︰China

Unit Price︰US $ 2.98 / kg

Minimum Order︰5000 kg

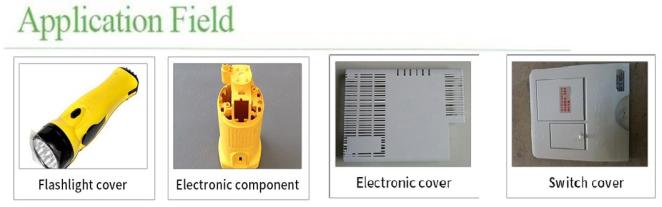

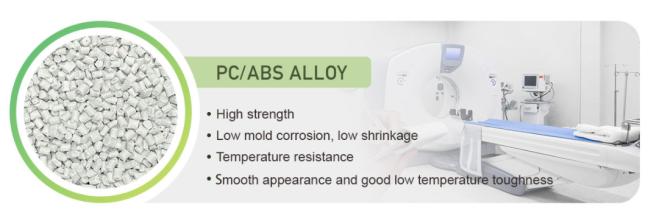

PC ABS is a thermoplastic alloy plastic of polycarbonate PC and ABS. It combines the excellent characteristics of the two materials. It has good forming and processing properties of ABS and excellent properties such as mechanical properties, temperature resistance, and UV resistance of PC materials. It also has the advantages of high impact resistance, high strength, low mold corrosion, and low shrinkage. All materials can meet ROHS environmental protection requirements and are widely used in the home appliance industry, electronic appliance, and automobile industry. Topology engineering plastic can provide customized services according to customers' specific requirements. It is your trusted modified plastic manufacturer.

PC/ABS(CA0108 NA)

| Product Description | Applications | ||||||||

| · Good dimensional stability | · Injection molding | ||||||||

| · Excellent heat stability | · Good mechanical properties balance | ||||||||

| Properties | Test Method | Test Condition | Unit | Typical Values | |||||

| Physical properties | |||||||||

| Specific Gravity | ISO 1183 | 23ºC | g/cm3 | 1.2 | |||||

| MI | ISO 1183 | g/10min | 60 | ||||||

| Ash | ISO 3451 | 800ºC,30min | % | 0 | |||||

| Mechanical properties | |||||||||

| Tensile Strength | ISO 527 | 50mm/min | MPa | 65 | |||||

| (yield) elongation | ISO 527 | 50mm/min | % | 70 | |||||

| Flexural Modulus | ISO 178 | 2mm/min | MPa | 2700 | |||||

| Cantilever beam notched impact strength | ASTM D256 | 23ºC | J/m | 15 | |||||

| Non-notched impact strength of cantilever beam | ASTM D256 | 23ºC | J/m | - | |||||

| Other properties | |||||||||

| Flammability | UL94 | 1.6mm | V0 | ||||||

| Note: The data above is a typical value for reference, not a guaranteed value. The data will vary with tool design such as gate type, gate location, gate number, injection molding process, and part thickness. The data will vary with different colors as well. Prior to use the material, please consult with TOPO NEW Material Co., Ltd. | |||||||||

| Processing Conditions | Range | ||||||||

| Melt Temperature | 230-250ºC | ||||||||

| Mold Temperature | 60-100ºC | ||||||||

| Pre-Dry needed | 90ºC, 3-4h | ||||||||

Note: The above process condition is only for reference. The actual process should be adjusted according to different types of machines, mold design, and product design.

Are you a trading company or manufacturer?

We are a manufacturer.

About Sample?

5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?

Quality is the Priority, we always pay great importance to quality from beginning to end, we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? is the sample free?

7-10 days to send free samples by DHL, TNT, UPS

Payment Terms︰ TT/LC